How ES Canada Helped The BE-Hive Ditch Manual Checks for Good

Smart Sensor, Smarter Production

At ES Canada, we don’t just distribute solutions, we deliver results. When The BE-Hive, a fast-growing vegan food manufacturer in Nashville, Tennessee, needed a smarter way to manage temperature monitoring across their facility, we stepped in along with Icicle Technologies to make it happen.

Their challenge was clear: too much time spent walking the floor with a temperature gun, and not enough time focused on production. Johnny, their Quality Assurance Manager, was losing 10+ minutes per day just checking temperatures across multiple zones. That’s time that could and should be spent on what matters most: making high-quality vegan products.

COMPANY PROFILE

The BE-Hive is a fast-growing vegan food manufacturer based in Nashville, Tennessee. Known for its commitment to quality and innovation, the company sought to modernize its temperature monitoring process to improve efficiency and product consistency.

CHALLENGE

The BE-Hive’s QA Manager, Johnny, was spending over 10 minutes daily manually checking temperatures across a 1,600 sq. ft. facility. This process was inefficient, time-consuming, and prone to human error. They needed a solution that could integrate with their existing Icicle food safety platform.SOLUTION

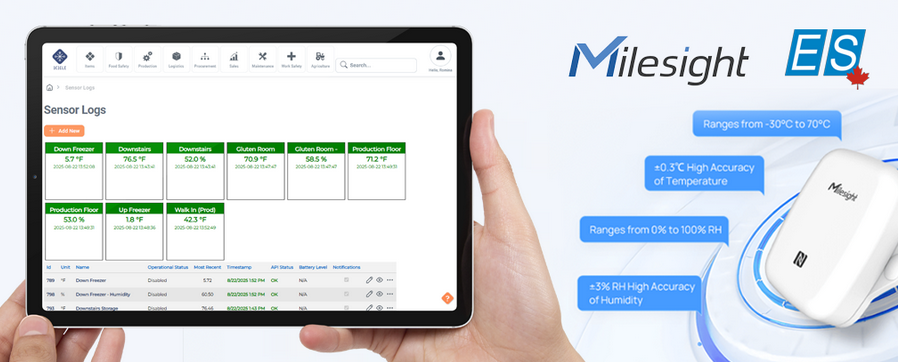

- Milesight EM300-TH sensors for temperature and humidity monitoring.

- A LoRaWAN gateway to transmit data wirelessly.

- Integration with Icicle for real-time visibility and alerts.

IMPLEMENTATION STEPS

1. Sensor Deployment

- Two Milesight EM300-TH sensors installed in the downstairs freezer and walk-in fridge.

- Non-invasive setup with minimal disruption.

2. Sensor Configuration & Activation

- Each sensor was configured using NFC (via the Milesight Toolbox) to confirm device IDs, reporting intervals, and measurement units.

- This step ensured the sensors were transmitting at the correct frequency and optimized for the project’s data needs.

3. Data Validation on Device Explorer

- Once connected, sensor data was monitored through Device Explorer to confirm successful transmission, verify measurement accuracy, and check for packet errors.

- Adjustments were made where needed to improve reliability and optimize performance.

RESULTS

1. Optimized QA Efficiency:

- Over 10 minutes saved per day on manual temperature checks.

- Staff can now focus more on production and quality assurance.

- Compliance with state regulation.

2. Real-Time Monitoring & Alerts:

- Automated alerts for temperature excursions across critical zones.

- Historical data is searchable and accessible from any computer in the facility.

3. Improved Product Consistency:

- Humidity tracking helps maintain ideal storage conditions.

- Reduced variability in product quality across batches.

TESTIMONIAL

“The initial pilot experience was rather easy on my end. The fact that it had such integration with Icicle was a big selling point for us. I didn’t have to learn a new system or change our workflow, it just worked.What really impressed me was how quickly we saw results. Within days, we had real-time visibility into our temperature zones, and the alerts gave us peace of mind we didn’t have before. It’s one less thing I have to worry about, and it’s freed up time for me and my team to focus on what we do best; making great vegan food.”

CONCLUSION

By partnering with ES Canada, The BE-Hive transformed a time-consuming QA process into a streamlined, automated system. The integration of smart sensors and real-time monitoring not only saved time but also improved product consistency and operational confidence.

This case proves that with the right technology, even small producers can achieve big results.