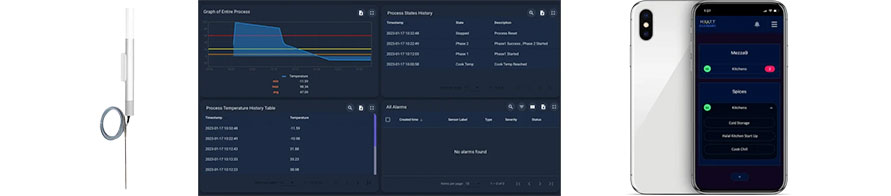

Food temperature monitoring with Senzemo IoT sensor

Challenges

- Existing food probe sensors in the market rely on outdated technology.

- Cables pose an inconvenience when attempting to assess temperature.

- Manual checks are necessary.

Solution

Presently, 70 specially crafted Senstick sensors have been dispatched to kitchens within the hotel chain, with plans for many more to be deployed shortly. These sensors conduct real-time readings at 10-second intervals, accessible on tablets, and also provide historical data. This enables chefs to oversee the cooking processes, leading to enhanced food quality, safety, and reduced waste.

Benefits

- Streamlining operations and enhancing efficiency in bustling kitchens.

- Elevated standards of food safety and quality, minimizing food waste.

- Adaptability for serving large quantities of food.

What is the Cook-Chill Process?

The Cook-Chill process is a widely adopted technique in the culinary industry, particularly by restaurants, hotels, and their chefs. This method of food production and storage involves cooking food at elevated temperatures to eliminate pathogens. Following this, the food is rapidly cooled to a temperature that inhibits bacterial growth, and it is then stored at this controlled temperature until it is ready for use.

Effectively implementing the Cook-Chill method offers several advantages. Firstly, it serves as a preventive measure against food spoilage and waste. By creating an environment where bacteria struggle to thrive, the process ensures the longevity of prepared food items. This not only contributes to sustainability efforts but also minimizes economic losses associated with discarded food.

Moreover, the Cook-Chill process is instrumental in mitigating the risk of foodborne illnesses. By adhering to stringent temperature controls during the cooling and storage phases, chefs can significantly reduce the likelihood of harmful bacterial contamination.

One of the notable benefits of Cook-Chill is its capacity to facilitate large-scale food production while maintaining quality and safety standards. Chefs can prepare substantial quantities of food in advance, allowing for efficient storage and subsequent service at a later time. This strategic approach not only streamlines kitchen operations but also helps in curbing food waste, fostering a more sustainable and cost-effective culinary practice.

In essence, the Cook-Chill process emerges as a pivotal technique, enabling chefs to balance efficiency, food safety, and waste reduction in the dynamic landscape of culinary operations.

Established in 1979, Tasty Fresh Co. is a family-owned and operated Australian business dedicated to delivering fresh, hot meals, snacks, and beverages directly to workplaces. Operating in Melbourne, Perth, Sydney, Newcastle, and Queensland, the company boasts four in-house industrial bakeries specializing in crafting high-quality pies, pastries, sausage rolls, and more.

With a presence in six outlets across four states, Tasty Fresh Co. caters to approximately 35,000 customers daily, deploying a fleet of 153 vans and handling up to 100,000 units per day. The company's success is made possible by the dedication of over 500 employees across Australia.

Given the substantial meal volume they handle, Tasty Fresh Co. employs the cook-chill method for certain meal preparations. The key to ensuring the success of this method lies in leveraging specialized technological solutions capable of delivering precise and accurate temperature measurements. This meticulous control over temperature ensures the quality and safety of the meals, reflecting the company's commitment to excellence in food service.

Discovering the Optimal Solution

Implementing the cook-chill method involves adhering to specific temperature requirements, such as maintaining a cooking temperature of approximately 75ºC. Additionally, it involves verifying cooling rates, ensuring that the product transitions from 60ºC to 21ºC within 2 hours and further cools from 21ºC to <5ºC within 4 hours. This stringent process is designed to minimize the risk of Clostridium perfringens bacteria re-vegetating and generating heat-stable SET toxins.

To address these precise temperature control needs, a tailored solution was imperative. The Senstick Food Temperature Probe STF30 emerged as the custom-made sensor of choice. Not only does it feature a robust casing and probe, but its firmware was also meticulously adapted to align with the unique requirements of this specific case. This bespoke approach ensures the reliability and effectiveness of the solution in maintaining the integrity and safety of the cook-chill process.

We have implemented a continuous monitoring system that provides real-time data for both the cook and chill safety verification processes. Introducing the world's inaugural set-and-forget, hands-free cook-chill system, users can effortlessly insert the sensor into a product, initiating the process. The temperature journey is monitored in real-time, enabling proactive measures to be taken. The system issues warnings and critical alarms, ensuring the kitchen remains fully informed and alert throughout the entire process.

The cook-chill probes are affixed to top-notch Senzemo sensors. Tasty Fresh relies on these sensor probes on a daily basis to oversee and authenticate the cook-chill process seamlessly, with no need for user interaction with the software. The system operates entirely in a "hands-free" manner. The server-initiated process kicks in as soon as the sensor reaches 75ºC. Once inserted, you can simply step away, and the sensor, coupled with the software, manages the entire procedure autonomously.

Tangible Advantages

This process eliminates the complexities associated with HACCP, being not only paperless but also intelligent and user-friendly. Users are unable to deviate from the true time/temperature monitoring, redirecting their attention to the core of the process—its behaviors and practices, which are integral to food safety. This transformation signifies a shift in managing cook-chill processes towards a technology-driven solution.